A client called with an interesting question: “We’ve been under the impression that all windows and exterior doors are supposed to be delivered with certified NAFS labels on them, and the labels are to be in place until the inspection is complete. On one of our current projects the window manufacturer wants to provide the label information on the shop drawings instead of putting individual labels on the products. Is this legitimate?”

My reply: “That’s a great question. And I’m glad you asked.”

I’ve been wanting to write about this question for some time, and that call gave me the opportunity. Most of this post, in fact, comes from my email reply. Here are my thoughts on the subject. I’d be interested to hear yours, so feel free to contribute to this discussion in the comments.

Where does the labeling requirement come from?

The requirement to label windows is set forth in CSA A440S1-09, the Canadian Supplement to NAFS, Clause 6.4, which requires:

- A “permanent marking” on each product “indicating the manufacturer’s identity in a location that is visible when the product is installed.” Generally accepted permanent markings include hard-to-remove labels as well as etchings in the corners of insulating glass units. As building occupants don’t like to look at labels, they are often applied to the edges of operable sashes where they can be seen only when products are the open position. For non-operable (“Fixed”) windows, label information is permitted to appear in inconspicuous locations such as under a glazing bead.

- A “performance rating label” indicating the product’s tested performance using NAFS Primary and Secondary Designators.

The Fenestration Canada organization has published several guideline documents, developed with industry consultation, to encourage consistency and best practices for performance rating labels. The NAFS Labeling Guidelines for Canada (November 2013) summarize the Canadian labeling requirements and provide examples of labels for various applications. Two more documents were published in September 2014: Voluntary NAFS Labeling Guidelines for Products with Mullions, and Recommendation on the Use of Engineering Calculations to determine Design Pressure Ratings of Fenestration Products under NAFS-08. These are must-read documents for anyone interested in Canadian NAFS labeling requirements.

Labels and certification

First of all, we should distinguish between labeling and certification, as the two concepts were conflated in the mind of my client. Labeling is not necessarily evidence of certification. There is no requirement in the Canadian Supplement, in NAFS, or in the Code for the labels to bear the mark of a certifying or verifying organization. Labels are fundamentally just the manufacturer’s declaration that the performance ratings on the label correspond to the tested ratings of the products under qualification methods permitted in the NAFS standard.

Many manufacturers elect to voluntarily enroll in certification programs, as a certification mark gives their label greater credibility. But many more do not see value in that. Either way, certification is a voluntary matter, and not a code requirement in Canada.

Individual Labels vs. Site Labels

Labels are not that popular on large buildings however. In British Columbia on Canada’s west coast where I work, on Part 9 multifamily buildings and on Part 3 buildings generally labels are not often used. Why? Well, site-glazed commercial products have never been labeled, as they qualify air-water-structural performance with Part 5 professional design and field review. This approach was extended to factory glazed products many years ago. So we have not had a history of labeling windows on large buildings prior to the introduction of NAFS.

Instead, on multifamily projects and Part 3 buildings a number of manufacturers advocate the use of project-specific “site-label” documents instead of individual labels on products. The site-label could be a separate document, or be incorporated into the shop drawings submitted by the manufacturer. The site-label or site-certificate paradigm has precedent for energy performance compliance under ASHRAE 90.1, and NFRC project-specific “label certificates” that are permitted in place of individual product labels on large buildings.

There are good reasons to accept the validity of the site-label approach:

- It facilitates review of performance ratings by the responsible professionals or building officials. Instead of examining many labels over the entire jobsite, a single document can be examined.

- It addresses the need to prevent individual labels from being removed prematurely, before they are inspected

- It provides a permanent record of the manufacturer’s declared performance ratings. Unlike a removable label that is removed after construction, the site label can be filed with project documents. When the site label information is on the project shop drawings, long term retention of the information is virtually assured.

The site-label approach, whether by a separate document or by incorporation into shop drawings, is in my view superior to individual product labeling from a project management viewpoint. It fulfills the intent of CSA A440S1 that the manufacturer should be identifiable, and it provides a record of tested ratings for the products provided to the project. Should there be any need to verify product performance ratings in the future, there will be a high quality record of tested ratings by the manufacturer available to interested parties.

Example

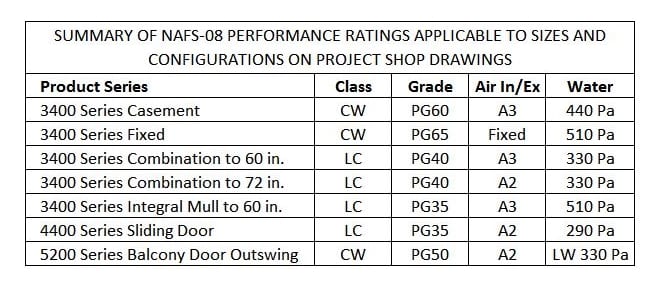

There are several ways to add NAFS performance rating information to shop drawings. One way is to add a table to the cover sheet or a notes page. More or less detail can be provided, depending on factors such as whether the project specifications call for the manufacturer to provide engineer-stamped shop drawings and letters of assurance. In such a case, the windows and doors will be designed to meet the project wind loads on the basis of the engineer’s design, and not on the basis of Performance Grades determined using the simplified methods of the Canadian Supplement.

This illustration shows how a NAFS site-label of performance ratings might look for a project specified to have windows, sliding glass doors and balcony swing doors for a three storey multifamily building specified to have products of Class LC – PG 30, water test pressure 290 Pa, Air Infiltration/Exfiltration Level of A2/Fixed.

What do you think of this way of reporting NAFS tested Performance?

Some may be surprised by this approach and some may object to it. To my mind, it satisfies the manufacturer’s obligation to report performance and be held accountable for it.

What do you think? Post your thoughts in the comments.