On January 21, 2016, RDH’s Michael Kramer, Bailey Brown, and John Straube attended the official launch of the 2016 Masonry Systems Guide: Northwest Edition in Seattle, Washington, at the Masonry Institute of Washington’s 2016 Masonry Symposium. There, the team of experts formally presented the guide and discussed the included assemblies and information.

The Making of the 2016 Masonry Systems Guide: Northwest Edition

Created with the oversight of professional building envelope consultants, engineers, architects, experienced commercial masonry contractors, and other masonry specialists, the guide is the product of decades of combined in-the-field masonry experience.

RDH played a critical role in the guide’s creation, drawing upon its long history of publishing guideline, policy, and best practice documents, with three of our engineers working extensively on the content development and production of the guide: Michael Kramer, Bailey Brown, and Graham Finch. Substantial input also came from RDH’s experienced team of researchers, including John Straube, who work with these assemblies and principles daily in the field and in the lab.

A Look Inside

The main focus of the 2016 Masonry Systems Guide: Northwest Edition is to provide comprehensive design and construction detailing information for 8 primary above‑grade wall assembly options successfully used in the Northwest climate that are composed of clay or concrete masonry as an adhered or anchored veneer or single-wythe CMU wall application. The focus for each assembly is to clarify the overall above-grade enclosure wall design as a system as it relates to managing heat, air, and moisture (both liquid water and vapor) transfer between the interior environment and exterior environment and to demonstrate the constructability of these structures to ensure long-term durability. Cladding considerations including attachment and installation methods are also addressed. Each assembly within this guide is addressed specific to the Northwest region—Washington, Oregon, and Idaho—and considers local climate, codes, and building preferences and practices.

The guide is broken down into three primary sections: an introduction, assembly chapters, and references/resources.

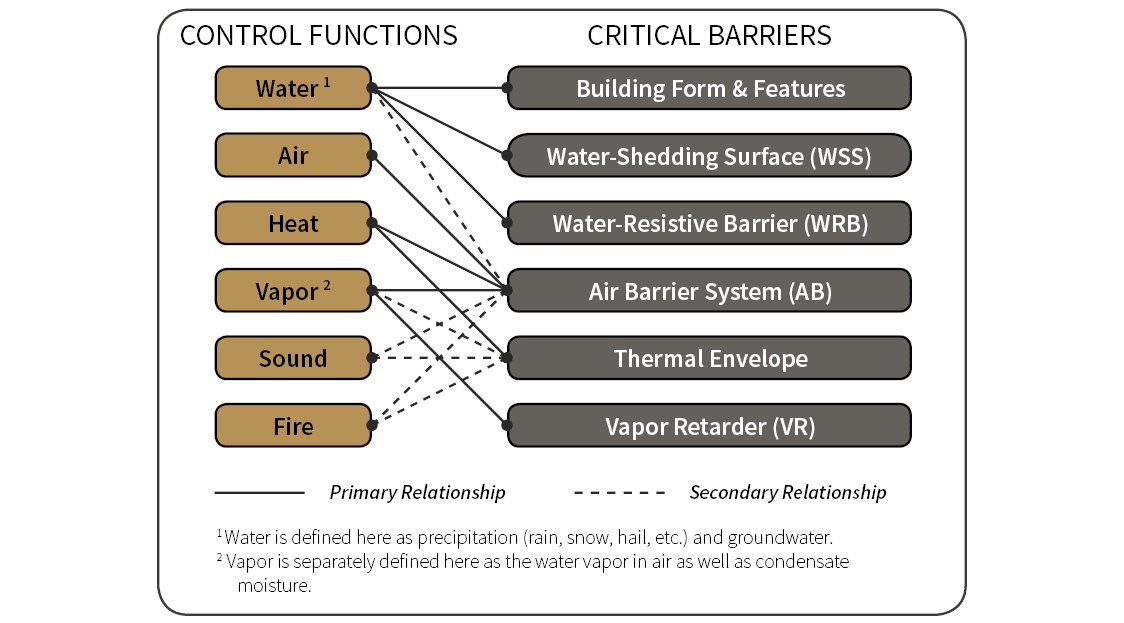

- Building enclosure system and loads

- Building enclosure control functions and critical barriers

- Thermal performance and energy code compliance

- Sheet-metal components and movement joints

- Cleaning, water repellents, and coatings

Each subsequent chapter is dedicated to one of the primary above-grade wall assemblies and provides assembly-specific discussion, guidance, photos, and/or diagrammatic illustrations. Two- and three-dimensional details and cutaway wall sections are provided at the end of each chapter, summarizing the chapter content and illustrating its use in real-world applications. The 8 primary above-grade wall assemblies featured are:

Chapter 1: CMU (or Concrete Alternate) Wall with Anchored Masonry Veneer

Chapter 2: Steel-Framed Wall with Anchored Masonry Veneer

Chapter 3: Wood-Framed Wall with Anchored Masonry Veneer

Chapter 4: Integrally Insulated CMU Wall

Chapter 5: Interior-Insulated CMU Wall

Chapter 6: CMU Wall with Adhered Masonry Veneer

Chapter 7: Steel-Framed Wall with Adhered Masonry Veneer

Chapter 8: Wood-Framed Wall with Adhered Masonry Veneer (Thick or Thin Bed Method)

A pricing analysis is provided in the chapters for each assembly and demonstrates the relative price per square foot. Pricing is for components outboard of the wall sheathing for framed or CMU backup wall assemblies. For exterior-exposed CMU wall systems, pricing includes all components except interior finishes and interior framing (where it occurs). Pricing is based on a 10,000- square-foot wall area and is valued for the 2015–2016 calendar year.

The sections following the 8 assembly chapters contain additional information regarding thermal modeling parameters, published industry references, and product resources. Additional features of the guide include design and construction/installation checklists and other design considerations as well as an assembly comparison matrix provided to assist designers with assembly selection, with comparison categories for both commercial and/or residential applications.

Accessing the Guide

Officially available on January 21, 2016, visit www.masonrysystemsguide.com for information about where and how to purchase the complete guide. The 2016 Masonry Systems Guide: Northwest Edition will be available in a hardcover book, via downloadable PDF, and online, with additional resources available through the website. Also available online will be downloadable digital versions of two- and three-dimensional assembly details and cutaway sections, as well as sample project specifications and updated pricing analyses.